SJD Designs.

Design Engineer | NPD Specialist | CAD Prototyping | Sustainability Advocate

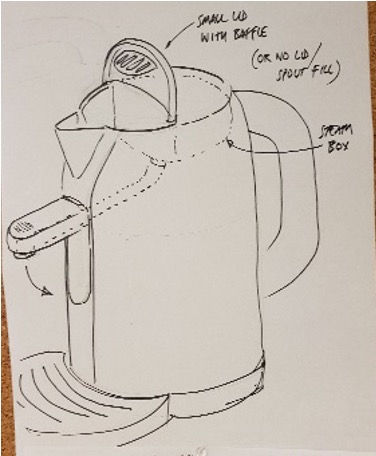

HotCup Duality – Combined Kettle & One-Cup Dispenser

Eliminates habitual over-filling, saving up to £12 per home and tackling a national £68 million energy-waste problem.

Goal:

Reduce the frequency of over boiling kettles in the UK by delivering a dual-function kettle and hot cup appliance, combining speed, convenience, energy efficiency and safety.

Timeline:

Jan – Sep 2019

Team:

3 Strix engineers + Kinneir Dufort (Contracted Consultancy) designers.

Placement Role:

Engineering Intern, Strix.

Patent:

PCT/GB2020/000123 – named inventor

Overview

Problem Statement & Market Context

The UK faces a significant energy waste issue due to kettle usage patterns.

75% of British households overfill their kettles, leading to environmental and economic impacts.

95% of households use kettles daily

40% boiling water five or more times a day

British households waste 2.6 million kWh of electricity daily from overfilling resulting in;

Costing £68 million annually to the economy.

70 million litres of water wasted daily.

Each household could potentially save £11-12 per year by boiling water more efficiently.

This inefficiency contributes to a national energy crisis.

My Role and Resposibilities

Engineering Intern at Strix Ltd working predominintely on;

Concept generation & CAD

Prototype build and lab testing

Mechanism, sealing and force optimisation

Patent data pack authoring and CAD DFM for OEM hand-off

Project Scope and Responsibilities

Combine kettle and dispenser in one appliance.

HotCup "mode": Meet hot-cup delivery < 45 s, 150-300 mL ±25 mL at ≥ 90 °C.

Kettle "mode": Preserve 1.7 L kettle capacity & 240 s boil time.

FOB target $18-22; secure IP for dual-mode mechanism.

Technical Process

Phase 1: Concept Research and Ideation

Conducted market and consumer research, leading to ideation sessions focused on speed, convenience, and energy efficiency.

Explored engineering feasibility and initial changeover concepts for combining kettle and hot cup functionalities in one device.

Collaborated with a design consultancy to refine the product concept based on feedback.

Phase 2: Prototype Development and Validation

Created and iteratively improved mock-ups, testing and modifying them to enhance system performance.

Evaluated multiple actuation methods (e.g., push-rod mechanisms, flap linkages) and user-interface designs.

Ran performance tests (e.g., dispense times, temperatures, noise) to benchmark against targets.

Incorporated feedback from consumer research and technical testing to refine functional prototypes.

Phase 3: Technical Optimisation and DFM

Addressed manufacturing challenges, cost, and weight issues by revisiting design specifics.

Conducted detailed optimisation of joint mechanisms and seals to improve durability and safety.

Prepared the prototype for manufacturer review, ensuring it met industrial and performance requirements.